Monday - Thursday 8am - 5:30pm

Friday 8am - 4:30pm

Saturday - Sunday By Appointment

WHEEL CONSTRUCTION

There is a good variety of ways of constructing wheels. Most alloy wheels are made in either one, two or three piece construction types. One piece is just what it says, a wheel made in a mold as a single piece. Two piece wheels are made of two separate pieces (center and barrel) that are usually welded or bolted together. Three piece wheels are made of three separate pieces. They have a center, and inside rim half, and an outside rim half. They are bolted together using the highest quality fasteners.

Manufacturing method is very important in the overall quality and performance of a wheel. Here are the most common types of manufacturing techniques employed:

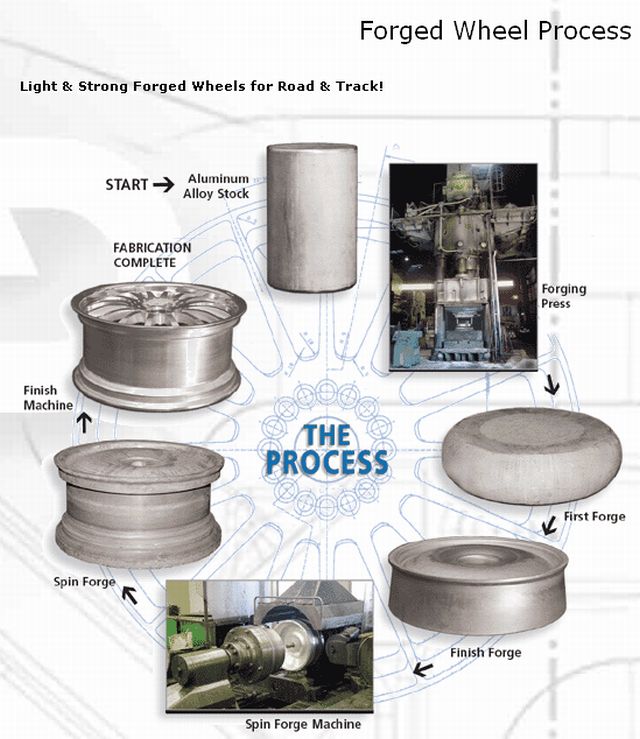

Forging:

Considered to be the best manufacturing technique, forging allows for the compression of an aluminum billet (one solid piece of aluminum) into an aluminum wheel using over 13 million pounds of pressure combined with heat. This produces a wheel that is both stronger and lighter then your standard aluminum wheel.

A subset of forging is called roll forging. In this process, a metal blank is run through rollers with impressions sunk in to their surface giving the wheel its final shape. This allows the wheel to be produced with less aluminum, reducing weight but maintaining strength.

Low Pressure Casting:

This is the most common form of rim manufacturing. Much like a casting, liquid metal is poured into a mold and allowed to harden until the finished wheel is cool enough to be taken out of the casting.

Counter Pressure Casting:

Opposite to low pressure casting, the liquid metal is not poured, rather it is sucked into the mould using a vacuum. This reduces impurities making the wheel much stronger than a low pressure cast rim.